Industrial sites like factories, warehouses, and manufacturing parks face fire risks every day from machinery, stored goods, and electrical setups. Zone-based fire suppression systems divide these large spaces into smaller areas, tackling fires right where they start without disrupting the whole operation. A smart fire suppression system like this keeps damage small and recovery fast. This guide covers everything you need to know about using them to manage risks effectively, drawing from real-world needs in busy Indian industrial areas.

What Are Zone-Based Fire Suppression Systems?

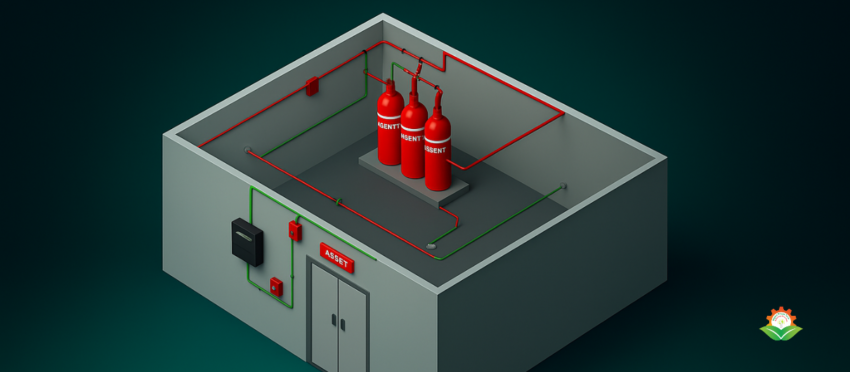

Think of your factory as a big puzzle—zone-based systems treat each piece separately. Instead of one giant setup flooding the entire building, they create protected zones: one for the paint shop, another for electrical panels, and so on. Sensors in each zone watch for heat or smoke, then release protection only there.

This approach shines in sprawling sites where fires can jump quickly through doors or vents. Gases, mists, or aerosols fill just the trouble spot, leaving other areas running smoothly. It’s like having a personal firefighter for every corner, perfect for places handling paints, oils, or electronics where blanket coverage would cause more harm than good.

In India’s industrial belts, from Ghaziabad to beyond, these systems match the mix of old and new factories, ensuring safety without halting production lines.

Why Industrial Sites Need Zoned Protection

Large facilities pack diverse risks—flammable liquids in one corner, dusty machines in another, sensitive controls elsewhere. A single fire can spread fast, shutting down shifts and costing lakhs in lost time. Overhead sprinklers soak everything, damaging goods and gear; zoned systems avoid that mess.

By splitting into zones, you control spread. A spark in the storage area stays there, while packing lines keep moving. This precision cuts cleanup time and keeps insurance happy with lower claims. Workers feel safer too, knowing help targets threats without full evacuations.

For growing operations adding new machines or sections, zones scale easily—no full redesigns needed.

How Zone-Based Systems Work in Practice

Setup starts with mapping your site. Divide by risk: high for chemical storage, medium for assembly lines. Install detectors and nozzles per zone, linked to a central panel that talks to alarms and doors.

When smoke rises in Zone 3, say the welding bay, lights flash, power cuts locally, and gas releases. Doors auto-close to seal it off, fans adjust elsewhere. Other zones stay alert but unaffected. Pre-set plans ensure even response, like extra cooling for hot spots.

Much like server room protections, this keeps critical paths open. Monitoring apps let managers check from phones, spotting patterns like recurring heat in one area for fixes.

Mapping Zones for Your Facility

Walk your floor first—note walls, doors, and airflow. High-risk zones get tight seals and fast agents; lower ones lighter coverage. Size matters: a 10×10 meter paint booth needs different power than a long conveyor hall.

Group similar risks—electrical panels together, storage separate. Allow overlap for tricky spots like shared vents. Experts sketch this digitally, balancing cost and coverage. In dusty yards, add filters; humid areas need moisture-proof parts.

Regular reviews update maps as layouts shift, keeping protection fresh.

Types of Agents for Different Zones

Choices fit the zone’s needs. Gases work best for electronics or controls—they vanish without trace. Mists cool machinery or goods without water damage. Aerosols suit enclosed spots like cabinets, floating to hidden flames.

Match to contents: oils need oxygen-cutters; wood dust suits wetting agents. Hybrids blend for mixed zones. Local suppliers tweak for India’s climate, ensuring reliability through monsoons or heat waves.

Test combos yearly to confirm no weak links.

Installation and Setup Steps

Planning takes a week, install a month for big sites. Start with pros assessing risks, then wire detectors and run pipes discreetly. Cylinders tuck in safe corners, controls central but accessible.

Test zone-by-zone: fake smoke in one, verify isolation. Train staff on signals—evacuate your zone only. Link to site-wide alarms for backups. Minimal downtime, big payoff.

Budget covers agents, hardware, and yearly checks—cheaper than one bad fire.

Daily Maintenance for Reliability

Light upkeep keeps zones sharp. Monthly walks check for blockages or damage. Quarterly, test sensors and pressures. Annual full drills simulate fires, refilling as needed.

Logs track it all for audits. In high-use areas, spot-check daily. Simple apps remind schedules, cutting oversights. Clean dust often—it’s a fire starter in itself.

Trained teams handle basics, pros the deep work.

Real Wins from Industrial Users

A Ghaziabad factory zoned its paint and assembly lines—a small oil fire stayed in one, resuming work next shift. No stock loss, minimal repairs. Another park contained a machine blaze, saving neighboring units.

Managers note fewer false alarms, smoother inspections. Production holds steady, tenants stick around.

Overcoming Common Challenges

Big sites worry about cost—start small, expand. Coordination across tenants needs clear rules. False triggers from cooking? Adjust sensitivities. Power cuts? Add backups.

Training bridges gaps—quick drills build habits. Regular audits spot drifts early.

Steps to Get Zoned Protection Now

Audit your risks today. Call local experts for quotes—they know industrial norms. Design, install, train, maintain. Compliance follows naturally.