In today’s competitive oil and gas environment, every decision made downhole has a direct impact on efficiency, safety, and long-term well performance. As wells become deeper, laterals extend farther, and completion designs grow more complex, operators need solutions that are reliable, adaptable, and cost-effective. At G&H Div, we specialize in advanced downhole completion tools that help operators meet these challenges with confidence.

Drawing from insights commonly shared across industry blog article transcripts, this post explores how modern completion strategies are evolving—and why the composite frac plug has become a key component in achieving efficient, streamlined operations. Our goal is to educate, inform, and highlight how G&H Div supports smarter completions from start to finish.

The Growing Importance of Downhole Completion Tools

Downhole completion tools play a critical role in preparing a well for production. These tools are installed after drilling and are designed to control flow, isolate zones, and support stimulation activities throughout the life of the well.

Why Downhole Completion Tools Matter

Effective downhole completion tools help operators:

-

Isolate multiple zones within a single wellbore

-

Improve hydraulic fracturing efficiency

-

Reduce non-productive time (NPT)

-

Enhance safety and operational control

-

Support long-term well integrity

At G&H Div, we approach downhole completion tools as integrated systems rather than standalone components. This system-focused mindset helps operators achieve consistent, repeatable results in even the most demanding environments.

How Completion Strategies Have Evolved

Traditional completion methods often relied on heavy intervention, extended milling operations, and time-consuming cleanouts. While effective, these approaches added cost and complexity. As industry blog article transcripts frequently note, the push for efficiency led to innovation in materials, design, and deployment methods.

Today’s downhole completion tools are designed to:

-

Minimize intervention after stimulation

-

Reduce operational steps

-

Perform reliably under high pressure and temperature

-

Adapt to diverse well conditions

One of the most impactful innovations in this evolution is the composite frac plug.

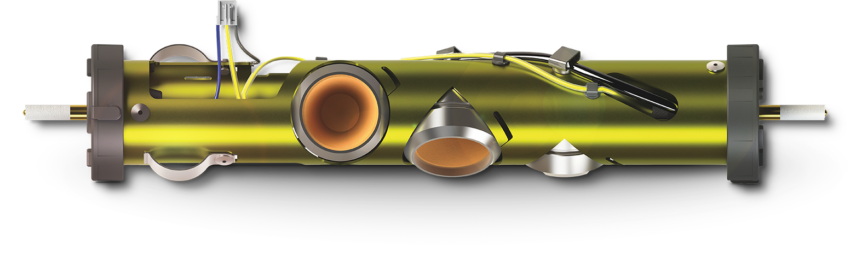

Understanding the Composite Frac Plug

A composite frac plug is a temporary downhole isolation device used during hydraulic fracturing. Unlike traditional metal plugs, composite frac plugs are constructed from engineered composite materials that are easier to drill or mill after stimulation.

What Does a Composite Frac Plug Do?

During multi-stage fracturing, a composite frac plug:

-

Isolates a section of the wellbore

-

Allows targeted stimulation of a specific zone

-

Withstands high pressures during fracturing

-

Is later removed efficiently through milling

At G&H Div, composite frac plug solutions are engineered to deliver dependable isolation while simplifying post-frac operations.

Benefits of Using a Composite Frac Plug

The industry’s shift toward composite materials is driven by measurable operational benefits. Based on field experience and insights from blog transcripts, operators value composite frac plug systems for several reasons.

Key Advantages

Using a composite frac plug can help operators achieve:

-

Faster milling times, reducing overall completion duration

-

Lower wear on milling equipment

-

Reduced debris size, improving cleanout efficiency

-

Reliable pressure isolation during stimulation

-

Cost savings through reduced rig and service time

These advantages make the composite frac plug a practical choice for operators focused on efficiency without sacrificing performance.

The Role of Composite Frac Plugs in Modern Completions

In modern horizontal wells with dozens of stages, reliability and repeatability are critical. A single failure can disrupt the entire completion schedule. That’s why composite frac plugs have become a trusted solution within advanced downhole completion tools portfolios.

Supporting Multi-Stage Fracturing

Composite frac plugs enable operators to:

-

Execute high-stage-count completions with confidence

-

Maintain consistent isolation between stages

-

Streamline the transition from stimulation to production

At G&H Div, we design composite frac plug systems to integrate seamlessly with other downhole completion tools, ensuring smooth operations from start to finish.

How G&H Div Approaches Downhole Completion Tools

At G&H Div, our philosophy is simple: tools should solve problems, not create them. Our downhole completion tools are developed with direct input from real-world operations, ensuring they meet the practical needs of today’s wells.

What Sets G&H Div Apart

Our approach includes:

-

Engineering-driven design focused on performance and reliability

-

High-quality materials suited for harsh downhole environments

-

Rigorous testing to ensure consistent results

-

Customer collaboration to align tools with specific well objectives

By offering advanced downhole completion tools, including dependable composite frac plug solutions, G&H Div helps operators reduce risk and improve outcomes.

Operational Efficiency and Cost Control

Efficiency is one of the most frequently discussed themes in industry blog article transcripts—and for good reason. Completion costs represent a significant portion of total well expenditure.

How Composite Frac Plugs Reduce Costs

Composite frac plug technology contributes to cost control by:

-

Shortening milling operations

-

Reducing equipment fatigue

-

Lowering the risk of stuck tools

-

Decreasing overall time on location

When combined with well-designed downhole completion tools, these benefits translate into tangible savings and improved project economics.

Safety Considerations in Downhole Completions

Safety is always a top priority in completion operations. Tools that reduce complexity and intervention inherently support safer workflows.

Composite frac plugs help enhance safety by:

-

Minimizing extended milling runs

-

Reducing debris-related complications

-

Supporting predictable, repeatable operations

At G&H Div, safety is built into every stage of tool development, from design to deployment.

Industry Trends Shaping the Future

The future of downhole completion tools is driven by innovation, efficiency, and adaptability. Industry conversations point to several ongoing trends:

-

Increased use of composite and advanced materials

-

Focus on reducing post-frac intervention

-

Demand for tools that support faster production timelines

-

Integration of completion tools into complete system solutions

G&H Div continues to invest in technology and design to stay aligned with these trends, ensuring our composite frac plug and other downhole completion tools remain at the forefront of the industry.

Real-World Results with Modern Completion Tools

Operators using modern downhole completion tools frequently report:

-

Faster completion cycles

-

More predictable operations

-

Improved well performance

-

Reduced operational risk

These outcomes reinforce the value of choosing the right tools for the job—and the right partner to support them.

Final Thoughts

As wells grow more complex, the need for reliable, efficient downhole technology becomes even more critical. Advanced downhole completion tools, paired with proven solutions like the composite frac plug, play a vital role in delivering successful completions.

At G&H Div, we are proud to support operators with tools designed to simplify operations, reduce costs, and enhance performance. By combining engineering expertise with practical field insight, we help our clients move confidently from completion to production—one well at a time.

When efficiency, reliability, and performance matter, G&H Div stands ready as your trusted completion partner.