Controller manufacturers in India have evolved from basic control panel suppliers to strategic partners in process optimization. The modern industrial temperature controller is not just a device; it is the operational heart of your heating system. Today’s purchase managers and engineers expect much more than stability; they seek process adaptability, long-term reliability, and integration readiness for Industry 4.0.

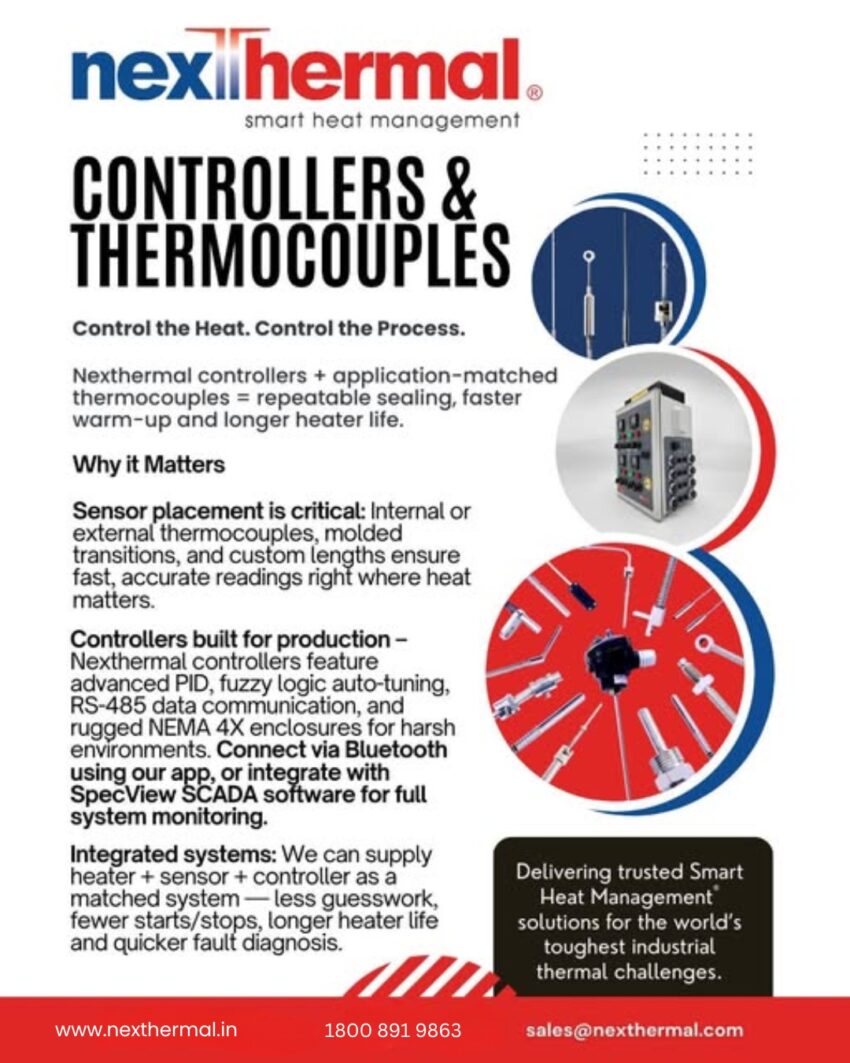

Over the past three decades, Nexthermal has consistently set new standards in custom heating and control engineering. Our solutions combine precision control, robust hardware, and advanced algorithmic intelligence to meet the unique challenges of Indian industries—whether it’s voltage inconsistencies, demanding climatic conditions, or complex production demands in plastics, automotive, and food processing.

30 Years of Insight: The Nexthermal Difference in the Indian Market

From our thirty years in the Indian industrial temperature controllers, we’ve learned that no two production environments are alike. A controller deployed in a beverage processing unit faces very different challenges from one used in an automotive seal line. Our focus has always been on creating customized industrial temperature controllers that fit the exact process profile, ensuring consistent output, minimal downtime, and extended equipment life.

Many Bangalore factories that once relied on generic imported controllers have switched to Nexthermal for more dependable operation. In one example from a food packaging plant near Hosur, replacing their imported controllers with Nexthermal’s custom-designed solutions improved uptime by 15 percent and reduced energy consumption by 12 percent. These measurable outcomes illustrate why local engineering experience matters as much as product sophistication.

Local Presence, Global Standards: Why a Bangalore Focus Matters

Bangalore’s position as India’s manufacturing and technology hub gives Nexthermal unique advantages. Our proximity to both global OEMs and local manufacturers allows us to combine quick response times with engineering precision. Whether it’s a rapid design modification or an on-site calibration requirement, our local presence ensures we can deliver what global suppliers often can’t—speed, flexibility, and contextual understanding.

Nexthermal controllers adhere to international benchmarks such as ISO 9001 and comply with relevant IEC safety and performance standards. From temperature control panels in extrusion lines to microcontroller-based systems in packaging machines, every unit reflects our commitment to precision and reliability.

By marrying global manufacturing standards with the realities of Indian process environments, Nexthermal provides users with the robust support and technical performance they need to stay competitive.

Decoding Application-Specific Control: Custom vs. Off-the-Shelf

For many years, Indian units relied on off-the-shelf controllers for all temperature-related operations. While these controllers are cost-effective, they often lack fine control when dealing with process-specific challenges like variable loads, rapid cycle times, or uneven heat distribution. Engineers often discover later that standard controllers limit production quality and throughput.

Custom industrial temperature controllers, on the other hand, are designed after analyzing the specific heating load, sensor characteristics, and thermal response time of each process. Nexthermal’s custom solutions deliver controlled power output, faster response, and finer tolerance management. These systems reduce manual intervention, improve the repeatability of results, and ensure consistency across every production batch.

Our controllers integrate advanced features like auto-tuning PID algorithms, thermocouple linearization, multi-zone control, and digital communication interfaces. Each module undergoes rigorous bench and field testing before release, ensuring accuracy and stability across a wide range of industrial applications.

The Critical Role of Temperature Sensors Manufacturer in a Control Loop

Every experienced engineer knows that control accuracy is only as good as sensor precision. A mismatch between the temperature sensor and controller can lead to process inefficiency, product defects, and erratic feedback. That’s why Nexthermal’s ecosystem includes its own line of electric heating elements and high-accuracy temperature sensors that are fully compatible with our controllers.

Partnering with Nexthermal means securing a tightly calibrated system—sensors and controllers that communicate seamlessly. Our thermocouples, RTDs, and resistance-based sensors undergo stringent linearization checks to maintain harmony between actual and displayed process values. For clients in PVC extrusion and thermoforming sectors, this precise synchronization has resulted in improved color consistency, smoother product finish, and lower power usage.

By offering sensors, controllers, and heaters under one roof, Nexthermal removes inter-component conflicts, ensuring reliability and high repeatability across temperature zones.

A Holistic Approach: Controllers, Elements, and Engineering Services

In the world of thermal management, isolating the performance of a controller from its heating elements often leads to partial optimization. Nexthermal’s approach is holistic: we deliver heating solutions where controller design, element engineering, and field integration all align perfectly. This single-source accountability simplifies procurement, speeds up project commissioning, and ensures consistent operation throughout the equipment life cycle.

Our engineering teams consult directly with plant heads and R&D engineers to map heating behavior under real-world operating conditions. For instance, in a recent injection molding application, we integrated cartridge heating elements with responsive Nexthermal controllers. The system reduced temperature overshoot by over 20 percent, shortened warm-up time, and stabilized product output—clear proof that synergy between hardware and control logic enhances performance.

Integrating Custom Heating Elements for Peak Performance

Heating element performance directly impacts controller efficiency. If the watt density, power distribution, or installation method is inconsistent, even the most advanced controller will struggle to maintain uniformity. That is where Nexthermal’s deep experience as a cartridge heating elements manufacturer plays a critical role.

Our heating elements are custom-wound and matched to the corresponding controller power stage. They are designed with optimal load characteristics for quick heat transfer and minimal energy loss. By integrating element design with controller tuning, our systems offer faster ramp-ups, tighter control, and longer element lifespan. For engineers working on precision demanding applications, this integration ensures every watt translates into measurable process output.

Thermal Engineering Services Provider in India: The Hidden Value of Consulting

Too often, industries treat heating control as a plug-and-play exercise, but in practice, minor inefficiencies accumulate into massive energy losses. As a thermal engineering services provider in India, Nexthermal partners with plants to assess thermal profiles and redesign control schemes for higher efficiency.

Our consultancy model goes beyond selling equipment. We perform detailed temperature mapping, energy audits, and retrofit evaluations. In one automotive sealing line, optimizing PID parameters and sensor configurations reduced power consumption by 10 percent, translating to significant annual cost savings. This approach demonstrates that the right consulting partnership can yield returns far beyond the initial equipment investment.

To explore how a Nexthermal controller can enhance your efficiency, Book a Free Technical Consultation with our team for customized recommendations and system evaluations.

Future-Proofing Your Plant: Reliability, IoT, and Support

Future-ready factories need controllers that don’t merely react but anticipate. With the rise of digital manufacturing, process control systems are expected to interact with broader networks through protocols like MODBUS, PROFINET, or Ethernet/IP. Nexthermal’s next-generation controllers incorporate IoT readiness, enabling real-time data sharing, predictive diagnostics, and integration with smart factory infrastructures.

These IoT-capable systems monitor energy usage, process temperature deviations, and heater cycle patterns to flag issues before failure occurs. For plants operating around the clock, this predictive layer offers substantial savings in unplanned downtime and batch waste.

Moreover, our controllers are equipped for easy firmware upgrades, ensuring that your system evolves as your production requirements change. This focus on long-term adaptability protects your investment for the decades ahead.

Ensuring Uptime: Support, Calibration, and Warranty

Service and support define reliability as much as product design. Nexthermal’s dedicated Bangalore-based network ensures timely calibration, technical assistance, and parts availability. Controllers are delivered with comprehensive documentation aligned with ISO traceability standards and backed by warranty coverage that underscores our production integrity.

Regular calibration programs maintain precision, while our field service engineers conduct on-site verifications to check drift or deviation. For large manufacturing facilities, our annual maintenance contracts help standardize control accuracy across multiple production lines.

Maintaining perfect calibration on your industrial temperature controllers directly translates into improved product consistency, reduced scrap, and smoother compliance with quality standards.

Connect with the Experts: Next Steps for Your Heating Solution

For more than thirty years, Nexthermal has built trust with manufacturers who see heating control not as a peripheral function but as a core productivity lever. Whether you operate in extrusion, sealing, molding, or packaging, our specialized solutions deliver measurable improvements in uptime and output.

To learn more about our range of industrial temperature controllers, visit our Temperature Controller manufacturer page or explore Our 30+ Year Legacy to understand how we’ve helped industries across India improve process performance and energy efficiency.

You can also reach us at 1800 891 9863 or Book a Free Technical Consultation today. Partner with Nexthermal—India’s trusted name in temperature control, heating elements, and comprehensive thermal engineering.

Book Your Expert Consultation: https://www.nexthermal.in/

Visit our service page: https://www.nexthermal.in/industrial-temperature-controller-manufacturers-in-india/

Connect Now: 1800 891 9863