Hydraulic cylinders are the backbone of countless industrial and mobile applications. From construction equipment to factory automation, they convert hydraulic energy into powerful linear motion. Among the most common types are single-acting and double-acting hydraulic cylinders. While both perform similar fundamental functions, their design, operation, and applications differ significantly.

Understanding these differences can help engineers, technicians, and equipment buyers choose the right cylinder for their specific needs.

What Is a Hydraulic Cylinder?

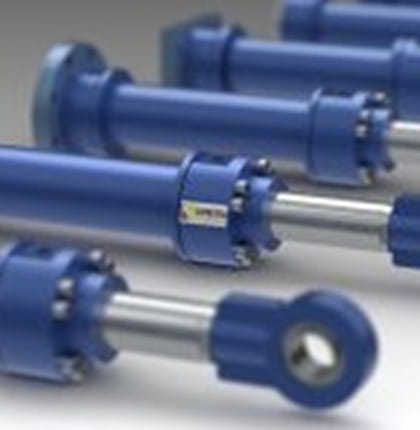

A hydraulic cylinder is a mechanical actuator that uses pressurized hydraulic fluid to create linear force and motion. The basic components typically include a cylinder barrel, piston, piston rod, seals, and end caps. When hydraulic fluid enters the cylinder under pressure, it pushes against the piston, generating movement and force.

The key distinction between single-acting and double-acting cylinders lies in how the hydraulic fluid is applied and how motion is controlled.

What Is a Single-Acting Hydraulic Cylinder?

A single-acting hydraulic cylinder uses hydraulic pressure to move the piston in one direction only. The return movement is achieved through an external force, such as gravity, a spring mechanism, or a load pushing the piston back.

How It Works

In a single-acting cylinder:

- Hydraulic fluid enters through a single port.

- Pressure pushes the piston in one direction (usually extension).

- When the pressure is released, the piston returns via gravity or a spring.

Because fluid is applied on only one side of the piston, these cylinders have a simpler internal design compared to double-acting models.

Key Characteristics

- One hydraulic port

- Force generated in one direction

- Simpler construction

- Typically lower cost

- Easier maintenance

Common Applications

Single-acting cylinders are ideal where force is only required in one direction. Typical uses include:

- Hydraulic jacks

- Dump truck beds

- Lifting platforms

- Simple pressing operations

For example, in dump trucks, gravity assists the lowering of the bed after hydraulic pressure lifts it.

What Is a Double-Acting Hydraulic Cylinder?

A double-acting hydraulic cylinder uses hydraulic pressure to move the piston in both directions—extension and retraction. It has two ports, allowing fluid to enter either side of the piston.

How It Works

In a double-acting cylinder:

- Hydraulic fluid enters one port to extend the piston.

- Fluid enters the opposite port to retract it.

- Both movements are powered and controlled by hydraulic pressure.

This design allows for greater control, speed regulation, and force application in both directions.

Key Characteristics

- Two hydraulic ports

- Powered movement in both directions

- Greater control and precision

- More complex construction

- Higher cost compared to single-acting cylinders

Common Applications

Double-acting cylinders are widely used in systems that require controlled motion in both directions, such as:

- Excavators and backhoes

- Industrial machinery

- Manufacturing automation systems

- Agricultural equipment

Heavy machinery like those produced by Caterpillar Inc. often relies on double-acting cylinders for precise control of arms, buckets, and attachments.

Key Differences Between Single-Acting and Double-Acting Cylinders

1. Direction of Force

- Single-acting: Force in one direction only

- Double-acting: Force in both extension and retraction

This is the most fundamental difference between the two types.

2. Number of Ports

- Single-acting: One port

- Double-acting: Two ports

The number of ports directly impacts system complexity and plumbing requirements.

3. Control and Precision

Double-acting cylinders provide better control because both extension and retraction are hydraulically powered. This allows smoother operation and more precise positioning.

Single-acting cylinders are less precise during the return stroke, as it depends on external forces.

4. Complexity and Cost

Single-acting cylinders are simpler and generally more affordable. They require fewer seals and less complex plumbing.

Double-acting cylinders are more complex and costlier but offer enhanced functionality.

5. Space and Installation

Single-acting cylinders often require additional space for springs or rely on gravity positioning. Double-acting cylinders may need extra hydraulic lines but do not depend on orientation for operation.

Advantages and Disadvantages

Single-Acting Cylinder Advantages

- Lower initial cost

- Simple design

- Easy maintenance

- Suitable for straightforward tasks

Single-Acting Cylinder Disadvantages

- Limited to one powered direction

- Less control over return movement

- Not suitable for precision tasks

Double-Acting Cylinder Advantages

- Full bidirectional control

- Greater operational flexibility

- Suitable for complex machinery

- Better speed and force regulation

Double-Acting Cylinder Disadvantages

- Higher cost

- More complex hydraulic circuitry

- Slightly increased maintenance requirements

How to Choose the Right Cylinder

Selecting between single-acting and double-acting cylinders depends on several factors:

- Application requirements: Is force needed in both directions?

- Budget constraints: Is cost a primary concern?

- Control needs: Is precise motion control required?

- System complexity: Can the hydraulic system accommodate additional lines?

If your application only requires lifting with gravity-assisted lowering, a single-acting cylinder may be sufficient. However, if controlled extension and retraction are essential, a double-acting cylinder is the better option.

Final Thoughts

Single-acting and double-acting hydraulic cylinders each serve vital roles across industries. Single-acting cylinders offer simplicity and cost-effectiveness for one-directional tasks, while double-acting cylinders provide power, control, and versatility for more demanding applications.

Understanding their key differences ensures optimal performance, efficiency, and long-term reliability in any hydraulic system.

Other recommended Link: What is a Hydraulic Cylinder? How it Works, Types, Uses